How to Apply Ceramic Coating and Achieve Professional Results

How to Apply Ceramic Coating and Achieve Professional Results

Blog Article

Just How Ceramic Finish Safeguards Your Vehicle's Paint and Maintains It Looking New

Ceramic finishing has actually arised as a sophisticated remedy for auto paint security, supplying a powerful barrier against the elements. The outcome is a significant reduction in paint deterioration and an enduring visual appeal.

What Is Ceramic Finishing?

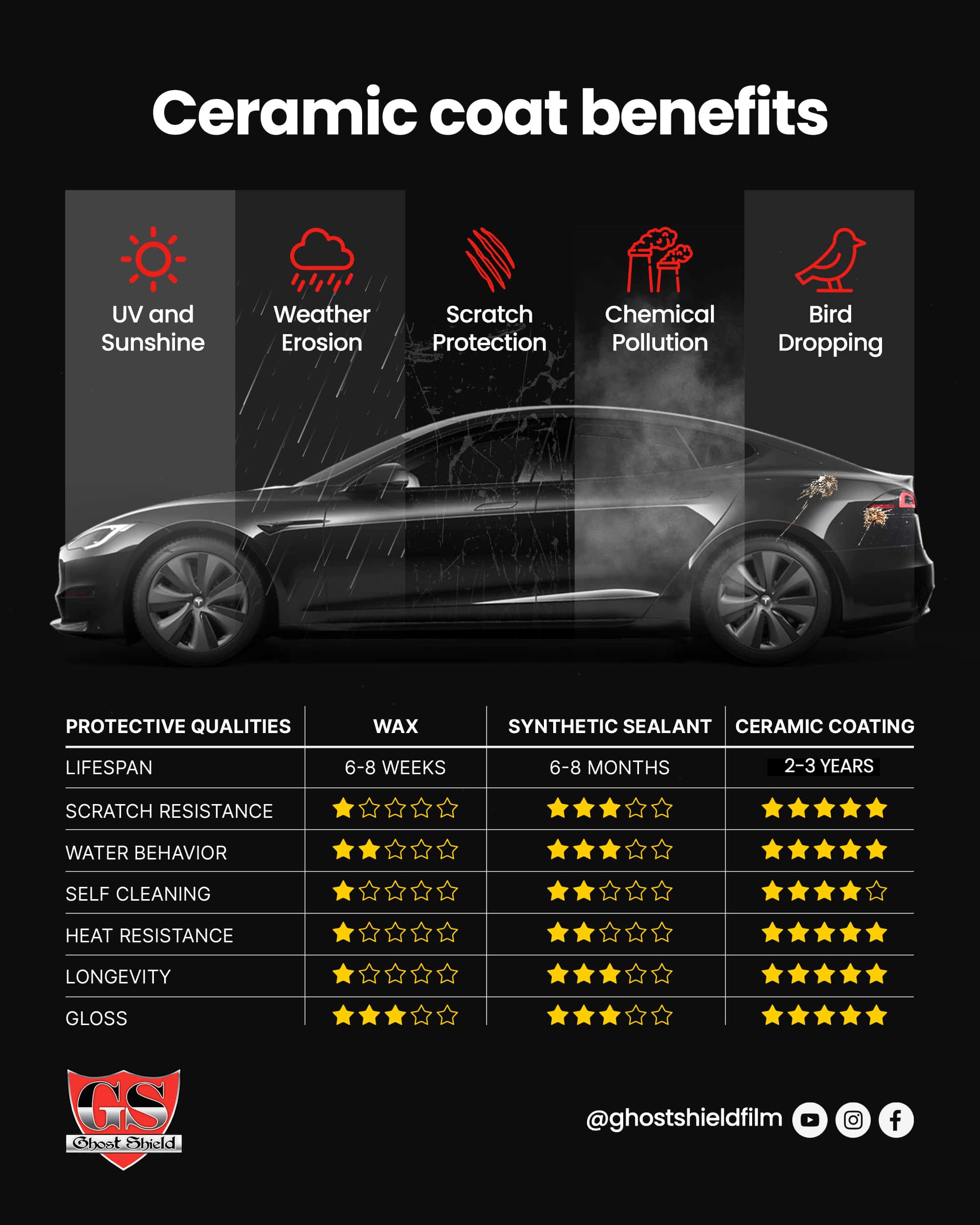

When used appropriately, ceramic finishes form a semi-permanent bond with the surface area of the vehicle, offering remarkable defense against UV rays, chemical stains, and small scratches - ceramic coating. Unlike traditional wax or sealants that might wear away within months, ceramic finishes can last for several years, depending upon the item and upkeep

The application process entails thorough surface prep work, including cleaning, sanitizing, and brightening the paint to ensure ideal attachment. As soon as the finishing is used, it cures and hardens, resulting in a hydrophobic surface area that drives away water, dirt, and grime. This hydrophobic building not just makes the car much easier to tidy but likewise improves the general gloss and clarity of the paint, contributing to a showroom-quality finish. Ceramic covering is increasingly favored by auto fanatics and specialists looking for resilient paint defense.

Advantages of Ceramic Finish

Why should vehicle owners consider purchasing ceramic covering? The advantages of ceramic layer expand much past plain looks, offering substantial defense and durability for a vehicle's paintwork. Among the main advantages is its phenomenal resistance to environmental pollutants. Ceramic coatings create a hydrophobic surface area, allowing water, gunk, and dirt to slide off quickly, reducing the regularity of washing and the requirement for typical waxes.

Additionally, ceramic coverings give a robust guard against UV rays, which can trigger paint to discolor and oxidize over time. This safety layer helps keep the vibrancy and gloss of the automobile's shade, guaranteeing it looks brand-new for years. In addition, ceramic finishings are known for their durability; they can last several years with correct upkeep, making them a cost-efficient investment in the future.

An additional significant advantage is the simplicity of upkeep they use. With a ceramic-coated surface area, minor scrapes and swirl marks are much less most likely to occur, and when they do, they are less complicated to rub out. Overall, the investment in ceramic layer not just boosts the aesthetic appeal of a car but additionally provides long lasting security that can conserve automobile proprietors time and cash.

Just How Ceramic Covering Works

Comprehending just how ceramic coating jobs is vital for auto owners considering this protective remedy for their automobile's paint. Ceramic finishings are composed of advanced nanotechnology that develops a resilient, safety layer over the surface area of the car's paint. When applied, these liquid polymers bond chemically with the factory paint, creating a solid, hydrophobic layer that repels water, dirt, and various other contaminants.

The key part in ceramic finishes is silicon dioxide (SiO2), which offers the coating's solidity and resistance to UV scratches, rays, and chemicals. This molecular bonding creates a protective shield that is substantially tougher than traditional wax or sealers, using durable protection. The hydrophobic nature of the finishing implies that water beads up and rolls off the surface area, taking dust and gunk click resources with it, consequently making the lorry simpler to clean up.

Application Refine of Ceramic Covering

The application procedure of ceramic finish requires careful preparation and attention to detail to ensure optimum outcomes. Originally, the vehicle must go through a thorough cleaning to get rid of dirt, crud, and contaminants. This step often includes a clay bar treatment to eliminate ingrained particles that might compromise the covering's adhesion.

Complying with the cleansing, a comprehensive evaluation of the paint surface area is necessary. Any type of existing flaws, such as scratches or swirl marks, need to be dealt with with polishing. This guarantees a smooth and reflective surface area, boosting the final appearance of the ceramic layer.

Once the paint is prepared, the ceramic coating is used in a regulated setting to prevent dirt and particles from polluting the surface. Using a specialized applicator, the coating is evenly distributed in sections, allowing for correct bonding with the paint. It is crucial to adhere to the supplier's standards concerning treating times and ecological conditions throughout application.

After the application, a healing period is needed for the finish to achieve its full safety properties. This process can differ in duration based on the details product made use of, however it is crucial for achieving the desired toughness and longevity of the ceramic finish.

Maintenance Tips for Ceramic Covering

Maintaining a ceramic finishing is essential for maintaining its protective homes and ensuring the longevity of your lorry's outside. Stay clear of automated cars and truck washes, as their rough chemicals and brushes can degrade the coating.

After cleaning, wash thoroughly and dry the automobile with a tidy microfiber towel to stop water areas. It's a good idea to perform upkeep washes every 2 weeks to keep the finishing Visit This Link in excellent problem.

Furthermore, take into consideration applying a committed ceramic coating booster or spray sealer every few months. These products improve the hydrophobic residential properties and include an extra layer of protection.

Inspect your automobile on a regular basis for any kind of contaminants such as tree sap, bird droppings, or roadway tar, and eliminate them without delay making use of a clay bar if needed. Park your auto in a garage or make use of a car cover to minimize direct exposure to extreme environmental components. ceramic coating. By following these maintenance tips, you can guarantee that your ceramic covering continues to be browse around this site reliable and your cars and truck maintains its display room luster

Conclusion

Finally, ceramic finishing works as a vital protective step for auto paint, supplying various advantages such as enhanced durability and resistance to environmental threats. The sophisticated chemical bonding process ensures a resilient shield against impurities, UV rays, and oxidation, therefore maintaining the vehicle's visual appeal. Appropriate application and maintenance are essential for making the most of the performance of ceramic coverings, eventually contributing to an automobile's longevity and preserving a showroom-quality finish with time.

Ceramic covering is a sophisticated safety service designed to improve and preserve the look of car paint. Ceramic layer is increasingly preferred by automobile lovers and experts looking for resilient paint security.

Comprehending just how ceramic finish works is important for car proprietors considering this protective service for their automobile's paint. Ceramic coatings are composed of sophisticated nanotechnology that creates a long lasting, protective layer over the surface of the auto's paint.The key element in ceramic layers is silicon dioxide (SiO2), which gives the finishing's solidity and resistance to UV scratches, rays, and chemicals.

Report this page